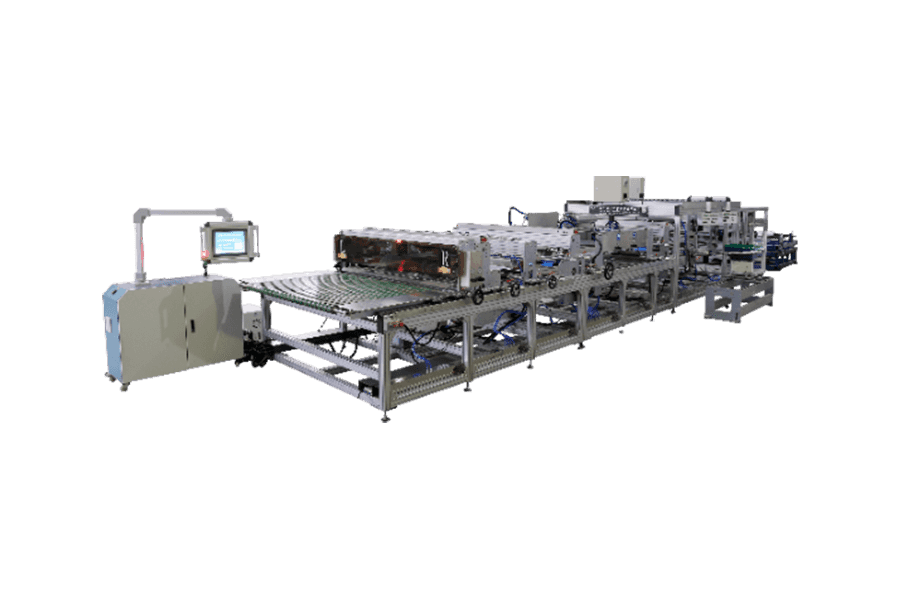

Với sự phát triển không ngừng của công nghệ thông minh, nhiều ngành công nghiệp đang trải qua quá trình chuyển đổi kỹ thuật số và ngành bao bì thực phẩm cũng không ngoại lệ. Máy làm túi thực phẩm t...

Thông báo mới nhất:

- Hiển thị thông tin Triển lãm Công nghiệp Nhựa và Cao su Quốc tế Châu Á - Thái Bình Dương lần thứ 21: Thời gia...

- Bảo trì máy túi giấy Vấn đề quá trình làm túi giấy của máy túi cần quan tâm? Máy làm túi giấy là một loại máy có thể g...

- Cách sử dụng máy túi giấy Máy làm túi giấy chúng tôi thường được sử dụng rộng rãi để đóng gói các loại quần áo mùa hè như á...

- Tại sao túi cột khí lại được ưa chuộng đến vậy? Hiện nay thị phần của bao bì đệm truyền thống như xốp, bông ngọc trai ngày càng nhỏ, sản phẩm bao...

Tin tức

TIN TỨC

Cung cấp cho bạn những tin tức mới nhất về doanh nghiệp và ngành

-

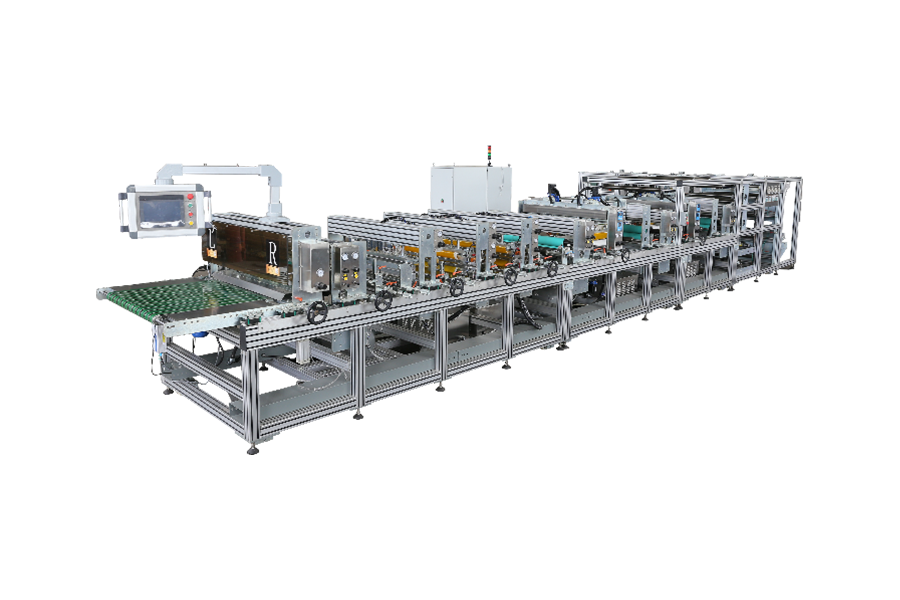

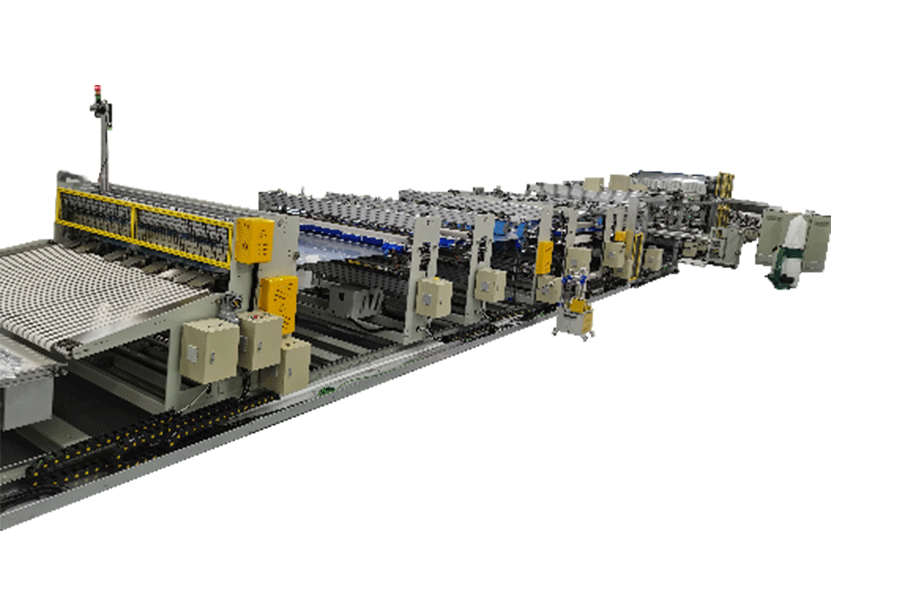

Làm thế nào để cải thiện khả năng tự động hóa bao bì thực phẩm bằng máy làm túi thực phẩm thông minh?

-

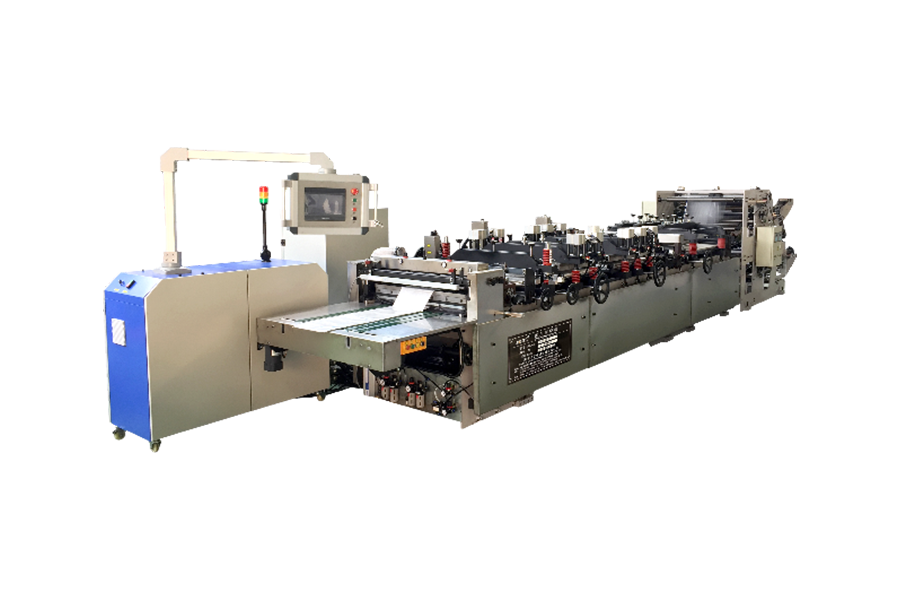

Máy làm túi đóng hộp thông minh BIB cải thiện chất lượng đóng gói và hiệu quả sản xuất như thế nào?

Trong lĩnh vực đóng gói cho các sản phẩm dạng lỏng, bán lỏng và chất lỏng có giá trị cao, bao bì dạng túi ngày càng được các thương hiệu áp dụng nhờ hiệu suất bịt kín chắc chắn, độ an toàn vận chuy...

-

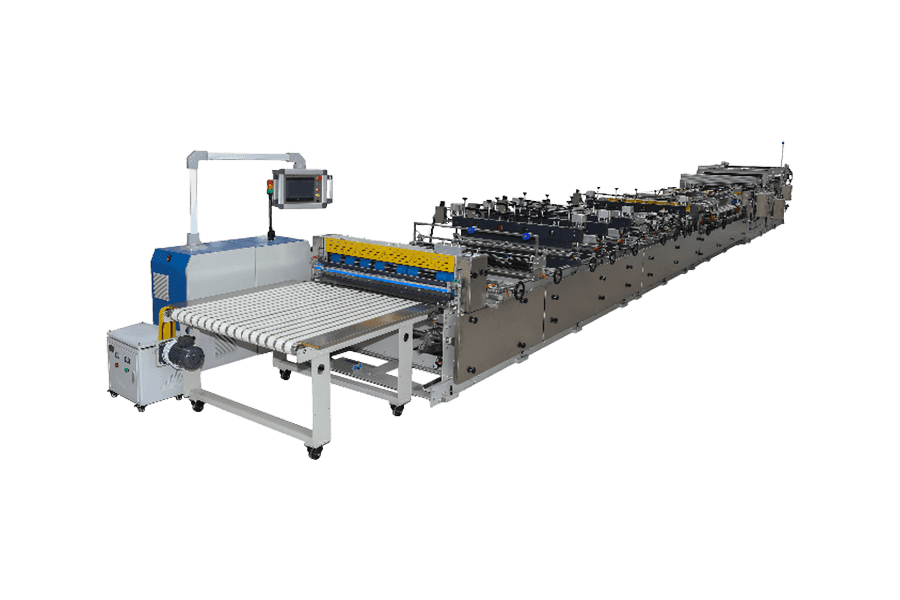

Máy làm túi lót thông minh: Làm thế nào để cải thiện độ chính xác và độ ổn định sản xuất của quá trình sản xuất túi lót?

Giới thiệu Trong lĩnh vực sản xuất bao bì hiện đại, túi lót, với tư cách là một dạng bao bì chức năng quan trọng, được sử dụng rộng rãi trong nhiều tình huống khác nhau như hóa chất, thực phẩm, ...